A diamond shape is an expression of personal style.

Krystal Grown Diamonds offers diamonds in thirteen gemstone shapes in both brilliant and step cuts. No shape is superior to another. Whether you’re interested in a brilliant cut with its triangular facets that capture and reflect the most amount of light, or a step cut with its large, stunning trapezoidal facets, Krystal Grown Diamonds guarantees that its diamonds are among the best cut in the industry.

This video clearly demonstrates the difference between the two cutting styles in two diamonds that have virtually identical overall dimensions. The Radiant and Princess Cut diamonds are brilliant cuts, whereas the Asscher and Emerald Cuts are step cuts.

Krystal Diamond can cut diamonds to custom specifications for antique, or non-traditional shapes for custom jewelry, or to be sold as a loose stone. Please inquire if you seek an uncommon shape.

Click on the Shape to Get More information about Diamonds shape

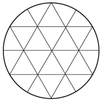

Circular in shape, and brilliant in style. The round brilliant is the most well known, most studied, and most popular diamond style of the last 100 years. The round brilliant has 58 facets, and it’s proportions are said to maximize for potential brightness.

Circular in shape, and brilliant in style. The round brilliant is the most well known, most studied, and most popular diamond style of the last 100 years. The round brilliant has 58 facets, and it’s proportions are said to maximize for potential brightness.

The cushion cut is the marriage of the round brilliant and radiant cuts with its square or rectangular shape and rounded edges. The cushion cut has no vertices. It is one of the most popular diamond shapes today.

The cushion cut is the marriage of the round brilliant and radiant cuts with its square or rectangular shape and rounded edges. The cushion cut has no vertices. It is one of the most popular diamond shapes today.

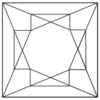

The Princess cut—also known as the Square brilliant—has the brilliance and fire of the Round Brilliant, but it is square in shape. This cut was perfected in 1979 by Israel Itzkowitz.

The Princess cut—also known as the Square brilliant—has the brilliance and fire of the Round Brilliant, but it is square in shape. This cut was perfected in 1979 by Israel Itzkowitz.  The Radiant Cut is octagonal in shape with clipped or cut corners, which make the gemstone easier to set in jewelry and more durable. Radiants can also be cut in either rectangular or square dimensions. This cut is also known as a Cut Corner Square Brilliant or Cut Corner Rectangular Brilliant.

The Radiant Cut is octagonal in shape with clipped or cut corners, which make the gemstone easier to set in jewelry and more durable. Radiants can also be cut in either rectangular or square dimensions. This cut is also known as a Cut Corner Square Brilliant or Cut Corner Rectangular Brilliant.

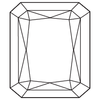

One of the oldest diamond cuts, it features large facets and cropped corners that draw light into the center of the stone, intensifying its brilliance and fire. Rectangular in shape, the emerald cut is a beautiful choice for Krystal’s best diamonds.

One of the oldest diamond cuts, it features large facets and cropped corners that draw light into the center of the stone, intensifying its brilliance and fire. Rectangular in shape, the emerald cut is a beautiful choice for Krystal’s best diamonds.

The asscher cut is similar to the Emerald cut, but is square in shape and more closely resembles an octagon. This cut is named in honor of Joseph Asscher, who perfected the emerald and asscher cuts in the late 19th century. Given their geometric symmetry, it makes sense that they would have been a staple in art-deco jewelry.

The asscher cut is similar to the Emerald cut, but is square in shape and more closely resembles an octagon. This cut is named in honor of Joseph Asscher, who perfected the emerald and asscher cuts in the late 19th century. Given their geometric symmetry, it makes sense that they would have been a staple in art-deco jewelry.

Circular in shape, and brilliant in style. The round brilliant is the most well known, most studied, and most popular diamond style of the last 100 years. The round brilliant has 58 facets, and it’s proportions are said to maximize for potential brightness.

Circular in shape, and brilliant in style. The round brilliant is the most well known, most studied, and most popular diamond style of the last 100 years. The round brilliant has 58 facets, and it’s proportions are said to maximize for potential brightness.

The pear cut diamond is an asymmetric teardrop and should be worn with the tapered end of the diamond pointing towards the wearer. There is dissimilarity in proportions of pear cuts. Though it is totally at the discretion of the wearer, we recommend a length to width ratio of 1.5-1.75 to maximize light return.

The pear cut diamond is an asymmetric teardrop and should be worn with the tapered end of the diamond pointing towards the wearer. There is dissimilarity in proportions of pear cuts. Though it is totally at the discretion of the wearer, we recommend a length to width ratio of 1.5-1.75 to maximize light return.

The marquise cut is oval with tapered ends with two points that are diametrically opposite to each other. Marquise diamonds vary in width, but we strive for symmetry between the two halves of our marquise diamonds. Because of their length and narrowness, marquise diamonds create an illusion of a larger size.

The marquise cut is oval with tapered ends with two points that are diametrically opposite to each other. Marquise diamonds vary in width, but we strive for symmetry between the two halves of our marquise diamonds. Because of their length and narrowness, marquise diamonds create an illusion of a larger size.

Rectangular in shape, baguette diamonds are similar to emerald cuts except they do not have clipped corners, and are narrower than emerald cuts. They were extremely popular during the deco era, but are still often used as accent stones next to larger diamonds.

Rectangular in shape, baguette diamonds are similar to emerald cuts except they do not have clipped corners, and are narrower than emerald cuts. They were extremely popular during the deco era, but are still often used as accent stones next to larger diamonds.

These triangular diamonds are primarily used as accent or side stones in three stone engagement rings.

These triangular diamonds are primarily used as accent or side stones in three stone engagement rings.

The heart shape is an undeniable symbol of love. They are most commonly worn as pendants or as engagement rings, though of course we could set one for you however you’d like it.

The heart shape is an undeniable symbol of love. They are most commonly worn as pendants or as engagement rings, though of course we could set one for you however you’d like it.

Rose cut diamonds are unlike any other shape offered by Ada Diamonds. They are dome-shaped with a rounded top and a completely flat bottom, which makes them easily set necklaces, cuff links, and stud earrings. Rose Cuts were very popular in the 18th and 19th century, but fell out of favor in the early 20th century as the dimensions of the Round Brilliant were perfected.

Rose cut diamonds are unlike any other shape offered by Ada Diamonds. They are dome-shaped with a rounded top and a completely flat bottom, which makes them easily set necklaces, cuff links, and stud earrings. Rose Cuts were very popular in the 18th and 19th century, but fell out of favor in the early 20th century as the dimensions of the Round Brilliant were perfected.

Do you want something other than what’s listed above? Krystal Grown Diamonds experts can cut our diamonds to whatever specifications you’d like.

Do you want something other than what’s listed above? Krystal Grown Diamonds experts can cut our diamonds to whatever specifications you’d like.

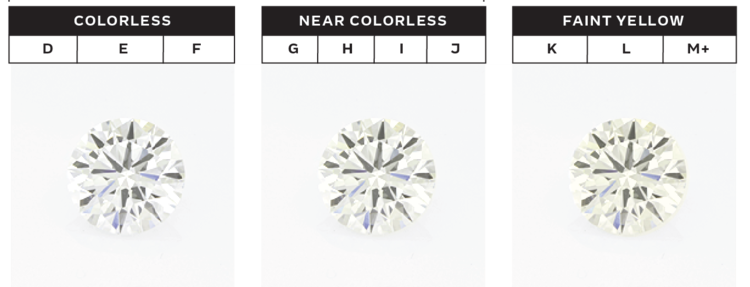

A perfect diamond, with no impurities and no defects, is completely colorless.

As the purity of the diamond decreases, the color of the diamond increases. The most common impurity in diamonds is clusters of nitrogen atoms inside the diamond. Over 98% of mined diamonds have nitrogen impurities, which give diamonds undesirable tints of yellow and brown.

In order to uniformly grade the color of diamonds, gemological laboratories have standardized on a range of letter grades of D-Z. as explained in the chart below. Krystal Grown Diamonds is proud to only sell diamonds that are colorless (D-E-F) or near colorless (G-H-I-J). Perfectly colorless diamonds are more desirable and therefore command a premium.

COLORED DIAMONDS

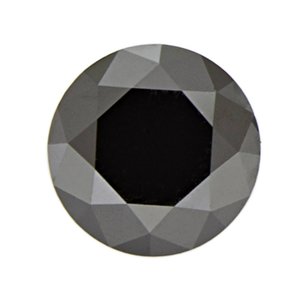

While it is extremely rare in nature, other impurities and crystal defects can result in a rainbow of colored diamonds: Red, Purple, Pink, Orange, Yellow, Green, Blue, Gray, and Black. These diamonds are classified as fancy colored diamonds, and less than 0.1% of mined diamonds receive this classification. Krystal Grown Diamonds can intentionally introduce trace elements into our diamond growth cells to create high quality colored diamonds.

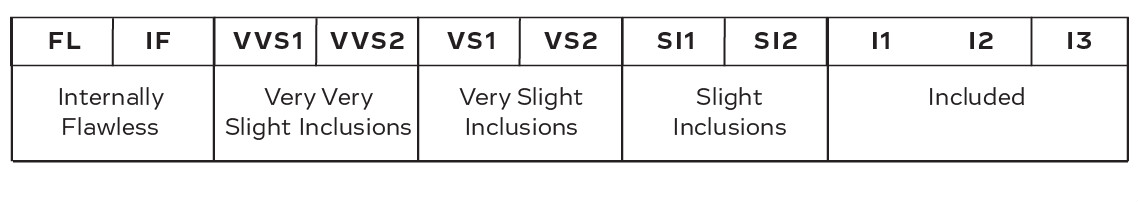

Clarity is a measurement of how many blemishes or inclusions are present in the diamond.

The lower the clarity of a diamond, the more imperfections in the diamond.

FROM FLAWLESS TO INCLUDED — FIVE MAJOR GRADES OF CLARITY:

The numbers after the major grade are a sub-grade, with the lower number being better. So a VS1 is superior to a VS2, which is superior to a SI1. Diamond clarity is graded by viewing the diamond through a 10x magnification with a tool called a loupe.

FLAWLESS AND INTERNALLY FLAWLESS (FL, IF)

Both FL and IF diamonds have no internal inclusions visible with magnification. IF diamonds may have very small blemishes present on the surface of the diamond, where as FL diamonds will have no internal or external imperfections.

VERY, VERY SLIGHTLY INCLUDED (VVS1, VVS2)

Imperfections are extremely difficult to locate with 10x magnification and impossible to see without jewelers tools.

VERY SLIGHTLY INCLUDED (VS1, VS2)

Imperfections are difficult to locate with magnification and not visible to the naked eye. A layperson would have difficulty finding inclusions even with 10x magnification.

SLIGHTLY INCLUDED (SI1, SI2)

Imperfections are easy to locate with 10x magnification, but are very difficult (SI1) or difficult (SI2) to see without a jeweler’s tools.

IMPERFECT (I1, I2, I3)

Imperfections are very easy to see under magnification and can be seen with the naked eye. Imperfect diamonds are more susceptible to cracking or breaking during daily wear. The majority of mined diamonds are of Imperfect clarity.

REDUCING INCLUSIONS IN THE LAB

Because the conditions in which our diamonds are grown are more controlled than the chaos produced beneath the Earth’s surface, Krystal Grown Diamonds only offer diamonds that are Slightly Included (SI) or better, with the vast majority of our diamonds having clarity grades of Very Slightly Included (VS) or Very, Very Slightly Included (VVS).

ADVANCED CLARITY

There are many types of inclusions in mined diamonds, but diamonds made in laboratories can have two types of inclusions:

FEATHERS are small fissures or cleavages in the diamond crystal. They occur when the crystal grows too rapidly under the Earth’s surface, or in a lab.

PINPOINT INCLUSIONS are microscopic pockets of non-diamond material present in the diamond that look like specks of dust in the diamond when viewed under a microscope. In lab diamonds, the foreign material is either graphite or metal. Pinpoint inclusions in mined diamonds can be one of two dozen types of different materials.

The cut of the diamond is a judgment of the quality of the shape, geometry, and finish of a diamond gemstone.

The Cut of the diamond is completely determined by the precision and quality of the methods used to cut and polish the diamond. Physicists, Material Scientists, and Gemologists have been studying diamonds for centuries to determine the exact dimensions of a diamond gemstone to get maximum light performance—the brightness, fire, and scintillation that makes diamonds so breathtaking.

Note that “Diamond Cut” does not refer to the shape or make of the diamond gemstone. The shapes that Krystal Grown offers can be seen above.

THE FIVE CUT GRADES

Gemological laboratories have 5 grades of cut: Ideal, Excellent, Very Good, Fair, and Poor. Krystal Grown Diamonds only offers diamonds with a Very Good or better cut grade.

LIGHT DANCES WITHIN THE DIAMOND

To understand the differences between an excellent cut diamond and a mediocre cut diamond, you must first understand how light interacts with diamond, as light is reflected and refracted in a very different way than in air, water, glass, or other gemstones. Diamond has a very high refractive index: light slows down in diamond, which creates the brilliance that sets diamonds apart.

THE ELEMENTS OF CUT

BRIGHTNESS is how much light you see when you view a diamond. A well-cut diamond has very specific dimensions that reflect and return virtually all of the light that enters the diamond back out of the top of the diamond. Even in poor lighting, a diamond can appear very bright. A poorly-cut diamond leaks light out of the bottom and is dull or flat when compared to a well-cut diamond.

FIRE describes the rainbow of colors reflected by the diamond gemstone. Diamond has an extremely high rate of light dispersion. When white light enters the diamond, it is spread apart into distinct colors in a prism-like effect.

SCINTILLATION defines the flashes of light that you see when the diamond moves. This is also called the sparkle of the diamond.

PATTERN is the contrasting light and dark areas in a diamond gemstone. The better the cut of the diamond, the better the contrast is between dark areas and light areas. Mediocre diamonds have blurry gray areas, whereas the best-cut diamonds have very distinct contrasting patterns that are uniform throughout the diamond. This phenomenon is called Hearts and Arrows in Round Brilliant shaped diamonds.

Krystal Grown Diamonds brings together human expertise and high technology to cut superior gemstones and exceptional jewelry.

No robot can cut and polish a beautiful diamond without human, and no human can thoroughly evaluate and precisely facet a rough diamond without technological support.

We have perfected our cutting process to meet the exacting standards of our company and our jewelry, and do not use traditional cutting operations in India and China where 85% of all mined diamonds are cut and polished today.

Our five-step process marries the best technology in the industry with the most talented artists in the world to produce superlative diamond gemstones.

1. 3D SCANNING

A laser scans the rough diamond crystal from all angles to build an exact 3D model of the diamond. Our lasers are able to detect every inclusion and blemish inside the crystal, as well as extremely precise external dimensions.

2. OPTIMIZATION ALGORITHM

This model is then fed into sophisticated software to guide our cutting teams to select what shape(s) should be cut from the rough stone. Some of our rough diamonds are cut into multiple gemstones, while others only yield one cut and polished diamond.

3. LASER CNC CUTTING

Our cutting team finalizes the shape and dimensions of the gemstone(s) and loads them into one of the most precise robots in the world. The robot cuts the most important facets of the diamond to ensure it has the most fire and brilliance. For a round brilliant, the CNC machine cuts 17 facets.

4. EXPERT HAND POLISHING

Highly talented diamond cutters, with decades of experience, spend hours perfecting the diamond into a beautiful gemstone. First, they inspect the diamond for any flaws, weaknesses, or problems. If the diamond is acceptable, the cutter will cut the additional facets in the diamond, and then spend hours polishing each facet to the highest quality. For a round brilliant, the cutter makes a total of 57 facets.

5. FINAL INSPECTION

The diamond is then passed to the master cutter for final approval. If they do not approve of the diamond, the entire process starts over with a much smaller diamond being cut from the subpar diamond.

6. INDEPENDENT GRADING AND LASER ENGRAVING

Once the head cutter has approved the finished diamond, it is shipped to an independent gemological laboratory for evaluation. This independent laboratory, which works with both mined and cultured diamonds, will evaluate the diamond and grade it on the 4Cs and also use a laser to engrave a unique ID on the girdle of the diamond.

Krystal Grown Diamonds’ jewelry design and fabrication processes celebrate and support the belief the fine jewelry production is a form of art.

It takes natural talent as well as years of mentorship and experience to develop the skills required to design beautiful jewelry, flawlessly cast settings in precious metal, and meticulously set diamonds in jewelry by hand. A complex design can take over 100 hours of labor to design and fabricate.

Krystal Grown Diamond has sought out the most talented artisans to fabricate and create all of our jewelry in the United States. Krystal Grown Diamonds delivers superlative jewelry to the most discerning customers and refuses to compromise on the quality of our setting. In other words, the quality of our jewelry must match the quality of our diamonds.

In order to achieve this level of quality, the majority of our pieces take four to six weeks to fabricate. We leverage technology to accelerate our communication and logistics processes as much as possible, without taking short cuts during the artisanal process. If you are working on a different tighter timeframe, one of our concierge members is happy to discuss what options are available with a quicker turnaround.

Our Jewelry Production Process

Designing Jewelry: We have sought out the best jewelry designers from around the world. Krystal designers will often start with hand-drawn pencil sketches of designs, and then create a computer model using modern CAD software.

Iterating with Customers: For custom designs, Krystal Concierge members and Designers work hand-in-hand with the customer’s feedback to perfect the jewelry design.

Printing the Wax Model: Once the design is complete, and a 3D model has been rendered, our fabricator will print a 3D model—the wax model—to ensure that is ready for casting.

Creating the Shell: To create a mold or shell to cast the jewelry, the fabricator hardens a liquid material around the wax model, and places it in a high-temperature kiln. In the kiln, the wax melts out of the shell, leaving a void in the shell that is the exact shape of the finished piece.

Casting the Metal – After it is tested and cleaned, the shell is placed in a centrifuge and spun at 20 times the force of gravity to ensure that molten recycled 18K gold or platinum completely fills the void in the shell. After the metal and the shell cool to room temperature, the shell is removed, leaving just the gold or platinum setting.

Polishing – The metal setting is then polished for hours by an expert goldsmith. They will use fine-grained materials to remove any artifacts from the casting process and polish the jewelry to a beautiful mirror-like finish.

Diamond Setting – After the jewelry is polished, the diamond(s) are hand set by an experienced bench jeweler who gently bends the metals around the gemstones to ensure that they are aligned as designed and secure. For jewelry with many small diamonds, the setting process can take multiple days of careful labor to get each gemstone perfectly set.

Final Polish and Plating – After the diamonds are set, the metal receives one last cleaning and polishing. For white gold and black gold jewelry, there is one additional step in the process – rhodium plating, which creates a surface that is resistant to scratching and tarnishing. Since Rhodium plating protects your jewelry, but does not last forever, Krystal Grown Diamonds recommends having your white and black gold jewelry plated every 3-20 years depending on use. We offer this service for free for life.

Photography – As a last step in the design process, Krystal Grown Diamonds will take high quality pictures and videos of your finished jewelry with professional camera equipment, which you can choose to use as you see fit. We recommend you share them with your insurance company if you choose to insure your Krystal Grown Diamonds jewelry.

Packaging and shipping – A member of the Krystal team will clean your jewelry one final time before placing it in our custom jewelry box and shipping it to you.